Connects what Belongs Together Intelligent Fastener Extension

- Easy handling of screws and dowel pins

- Define the sizes and holes in an intuitive dialog

- Assemble fasteners together with all holes

- Integration and use of existing fasteners

- Easy redefinition and removal

Benefits for your company

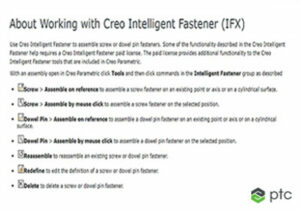

Intelligent Fastener Extension (IFX) provides quick and easy access to a screw and dowel pin library. The fasteners are created and installed together with all necessary boreholes.

- Fast and uniform access to fasteners

- Extensive fastener library

- Manage fasteners from catalogs

-

Uniform

Increase standardization in your company by using uniform standard parts libraries. For visualization, you can simply define your favorites.

-

Timesaving

In the IFX dialog, select the desired screw together with all washers and nuts and define the corresponding holes. IFX does the rest for you.

-

Flexible

After installation, you can quickly and easily redefine the screw/pin connection. This increases the flexibility to react quickly to changes.

-

Clear

Your existing connections are displayed with all necessary information in a dialog. From there you can easily edit the connections.

Videos

Here you will find a selection of current videos that will

bring IFX closer to you.

Functionalities

Assemble Screw Fastener

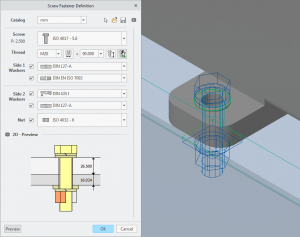

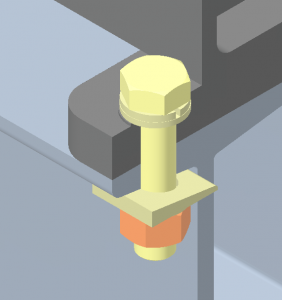

Simply select the position references for screw and nut/thread. Then define type and diameter, washers and bores. IFX assemble the parts together with every required hole.

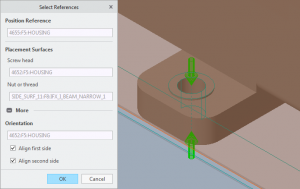

1. Select Reference

2. Define Screw Fastener

3. Assemble Models Together With Holes

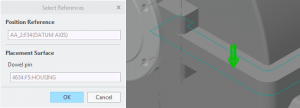

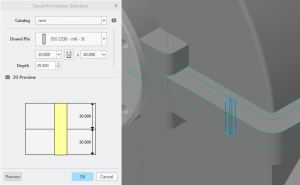

Assemble Dowel Pin Fastener

Simply select the position references for the dowel pin. Then define type, diameter and bores. IFX assemble the parts together with all the required holes.

1. Select Reference

2. Define dowel pin fastener

3. Assemble dowel pin together with all holes

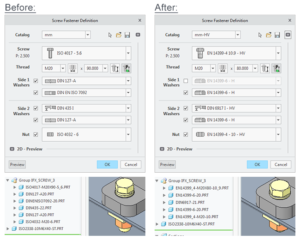

Redefine Fastener

Existing fasteners can be changed again with a few clicks. The parts are replaced and the holes adjusted.

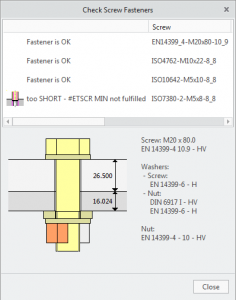

Check Screw Fasteners

All existing screw fasteners can be displayed in a dialog. The fastener lengths are checked and can be changed directly.

Create Instances

All parts of the library can be created using the instance creator. It is then easy to integrate the parts into the file management system.

Accessing Windchill files

IFX offers full Windchill support. All Creo® models of fasteners, catalog files and fastener data files can be stored in Windchill.

Customize Library

The library can be easily configured and adapted to your requirements. Add new catalogues and adapt the assortment of fasteners to your needs.

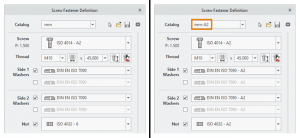

Manage Fasteners In Catalogs

Group logically related fasteners into new catalogs. This way you can prevent, for example, that an A2 screw is accidentally screwed together with a steel nut.

Abrufbare Normteile in IFX

Available Standard Parts in IFX:

- ISO®

- Holo-Krome®

- HELICOIL®

- Nord-Lock-Group

- PennEngineering®

- DIN

Request Demo Version

Have we aroused your interest?

Then you are welcome to request a demo version from us here.

Technical details

Find out about the supported Creo® versions

in our product calendar.