Tooling

Basically, a tool shop manufactures and assembles tools and fixtures that are used for the efficient production and assembly of workpieces and products.

Toolmaking can be roughly divided into the following process-related areas:

- Forming tools, which include, for example, punching tools

- Primary forming tools with the major areas of foundry and injection molding tools for plastics

- Jig and gauge design

In most cases, tools are custom-made and therefore very costly to manufacture. The total lead time for manufacturing a tool is usually several weeks or months, with an increasingly large proportion of time taken up by the development phase.

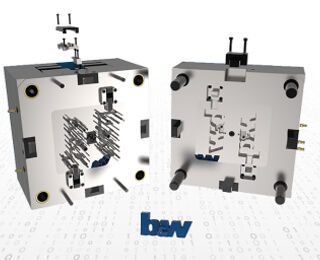

With our integrated software solutions Expert Moldbase Extension and Progressive Die Extension, we support the design of injection molds and progressive dies in order to map the respective very time-consuming design processes as intuitively as possible or to automate them in parts.

In both cases, a large number of standard parts adapted to the process are usually used to construct the molds. These parts are already included in the software packages as CAD models and can be intuitively assembled.

Independently of this, you can of course also use the library for screw and pin connections (Intelligent Fastener) integrated in Creo Parametric, which allows the intelligent assembly of standard parts via a special user dialog.

Further process flow

In the further process flow of the design, further software tools can be helpful in the area of documentation to facilitate work. This can be the automatic derivation of associative hole tables (SMARTHolechart), or assistance in applying hatching to large assembly drawings (SMARTXHatch), which accelerates or automates very time-consuming subtasks during drawing derivation.

In modern documentation processes of a tool design, the color coding of surface and tolerance specifications is indispensable. With SMARTColor we support the process in that already known properties or boundary conditions from the design are used by the software to largely automate the color assignment by means of a set of rules.

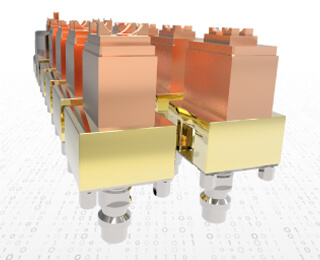

Spark erosion process

For the manufacturing process of the shaping parts of an injection mold, the spark erosion process is used in many cases. These special electrodes made of copper or graphite are used to produce areas of a cavity which cannot be manufactured using machining processes or which are to have a specific surface structure. The SMARTElectrode software can be used to simplify and standardize the individual design steps and then automatically export the transfer data to the production machine.

Products

Our software for a more convenient and automated setup of injection molds and

progressive dies, as well as the derivation of electrodes for the die-sinking

EDM process and passing on the PMI can support your work.

-

Expert Moldbase Extension

Expert Moldbase Extension

Expert Moldbase Extension (EMX) simplifies the design of injection mold tools through a flexible tool design and associative function groups such as ejectors, screw connections and cooling systems.

More details -

SMARTElectrode

SMARTElectrode

Create your sinking electrodes in a parametric world! The fully integrated software solution SMARTElectrode will speed up your design tasks in this area.

More details -

SMARTHolechart

SMARTHolechart

SMARTHolechart relieves you of the hours of work involved in adding drilling information and offers intelligent creation of hole charts. Rotational geometries are recognized automatically and hole types can be classified individually.

More details -

Progressive Die Extension

Progressive Die Extension

Progressive Die Extension (PDX) is the fully integrated industry solution for an efficient design of progressive die tools and allows you an easy creation and flexible modification of the strip layout and the tool itself.

More details