Sys2PEP - System models as a tool for the digital product development process

A research project funded by the Central Innovation Programme for SMEs of the Federal Ministry for Economic Affairs and Energy. Conducted by B&W Software GmbH, the Institute for Product Engineering at the University of Duisburg-Essen (IPE) and SMS group GmbH.

Problem

Product families with different variants in their operating principles and designs often prove to be complex in their development process. This results in high expenditure of time in construction and design. Usually the same users carry out such orders. Therefore there is a central accumulation of knowledge among a small group of people. In order to make the process of creating products efficient and accessible, system-technical support is unavoidable.

Solution approach

The product family will be transferred into a reference architecture using a formal description language. Through this, several elements are modeled and described by dependencies, attributes and important parameters.

Based on defined calculation and design rules, different configurations of the product will be generated. Finally, these will be transferred into a 3D model.

Implementation

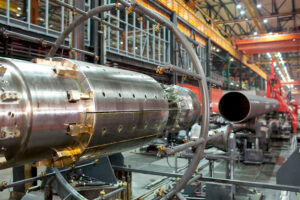

To create this process we used the product family of expander tools from the SMS group. This product family has a high variation in its design depending on the customer requirements. In view of this, this tool was suitable for this project.

With the help of a reverse engineering approach, it was possible to analyse the product to its functional architecture in a top-down process. The project partners identified the logical relationships between the structural elements through a continuous knowledge transfer. IPE described the reference product architecture using the system modeling language SysML.

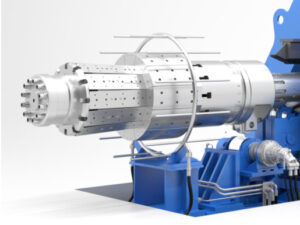

The Model-Based-Systems-Engineering (MBSE) environment “Cameo Systems Modeler” graphically represented the interrelationships of the product family. As a result, it provided the geometric characteristics of a product configuration in the form of parameters. SmartAssembly, which we developed, transferred the results between the MBSE and CAD systems. This gave us a high degree of flexibility. Moreover, it allowed us a quick reaction to the changing requirements of the product development process. The interface between the two systems was an XML structure.

The tasks on the CAD-system side consisted of transferring the XML data into a 3D model and designing safety-critical features. For this purpose, we created various analysis models and stored decision-making mechanisms in them. Using these, it was possible to check safety-critical elements and determine a design for some components. Due to extreme effort in describing such features in MBSE, this was very helpful. In addition, we created a structure in the CAD system that controlled the placement of components. As part of this process, we modeled the product in its rough structure as a skeleton. Afterwards, we adapted it to the variant and calculations using SmartAssembly.

Conclusion

By using a formal description language, it was possible to transfer the physical structure of the product with all its dependencies into a digital reference structure. As a result, the design of the finished product was fast and reproducible, taking customer requirements into account. By using SmartAssembly, we were able to react extremely flexibly to the variable requirements between the MBSE and CAD environments. At the same time, it was possible to transfer the calculation results into a CAD-System. The combination of the strengths of the two systems made it possible to design and validate even complex and safety-critical features.

Based on this research project, we created a new product development process through the cooperation of all project partners. With its help, it is possible to extract the existing know-how of a product family into a digital structure and then transfer it into a 3D-model.