New Functionality for Hole Charts in IFX

In this blog post, you will find out which enhancements are available for creating holes for screw fasteners and how to use them. In the next blog post on this topic, you will learn how to use the enhancements for dowel pin fasteners.

Note: The enhancements are available from Intelligent Fastener Extension version 7.0.3.0 and 8.0.0.0.

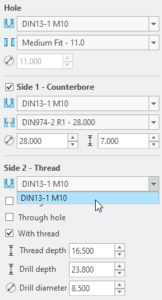

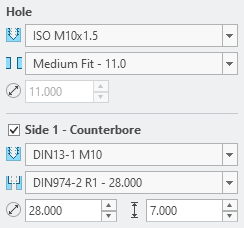

Overhaul hole layout

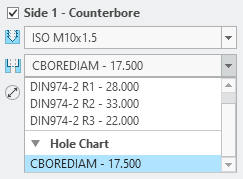

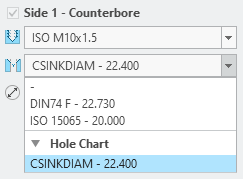

The hole layouts have been overhauled. Besides the possibility to select the hole chart, new icons have been added to make it easier to read.

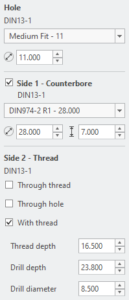

Comparison using the example of a screw-in connection:

| Before | After |

|

|

Select hole chart

In previous versions, the first possible hole chart (.hol) was always used for a hole. There was only the possibility to make a preselection via the SCR_THREAD_SERIES_* options for all hole types.

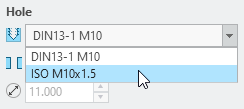

Due to the extension it is now possible to select the hole chart directly in the dialog. With this, e.g. different hole notes can be generated.

Note: The Creo configuration option hole_parameter_file_path can be used to specify a path to custom .hol files.

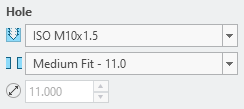

Example: For a screw with a diameter DN=M10 and a pitch P=1.5 two .hol files where found.

Preselect hole chart

Within a fastener data file (.dat) a .hol can now be easily specified for each fastener using the new THREAD_NAME keywords.

Use of THREAD_NAME

If you use the THREAD_NAME keyword, this .hol will be used for each hole type. It is then NOT possible to select another .hol.

Example:

| THREAD_NAME DIN13-1 | THREAD_NAME ISO |

|

|

Use of different THREAD_NAME_*

You can also use a different .hol for each hole type. The following keywords are available for the different hole types.

- THREAD_NAME_CLEARANCE – for clearance holes

- THREAD_NAME_COUNTERBORE – for cylinder counterbores

- THREAD_NAME_COUNTERSINK – for cone countersinks

- THREAD_NAME_THREAD – for thread holes

Example: ISO should be used for the clearance hole and DIN13-1 for the cylinder counterbore.

THREAD_NAME_CLEARANCE ISO

THREAD_NAME_COUNTERBORE DIN13-1

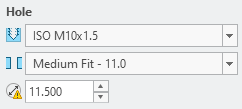

New options for clearance holes

CLEARANCE_HOLE_DIAMETER_OVERRIDE

The option can be used to specify whether the diameter of the through hole can be changed or whether the value from the .hol file is used. As soon as the diameter deviates from the default values, this is indicated by a warning.

| CLEARANCE_HOLE_DIAMETER_OVERRIDE | |

| NO | YES |

|

|

Possible values for the option:

- CREO_DEFAULT – Use the value of the ‘hole_diameter_override’ Creo configuration option.

- yes – Allow specifying the clearance hole value, instead of the standard value.

- no – Use the standard clearance hole diameter value.

CLEARANCE_HOLE_USE_LIMITS

With this option it is possible to ignore the limit values. The hole can be selected smaller than the screw diameter and larger than the head diameter.

Possible values for the option:

- yes – Set limits for min. and max. clearance hole diameter.

- no – Do not set any limits for the clearance hole diameter.

Add CBOREDIAM and CSINKDIAM for counterbores

In addition to the CBSCR and CBNUT diameters from the ifx_screw_data.cfg, the CBOREDIAM and CSINKDIAM counterbore diameters from the hole chart are now also available.

|

|

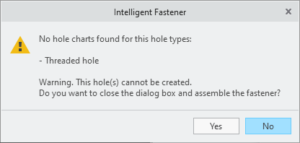

Error – Hole chart not found

If a .hol is specified which is not found, the selection field remains empty. Then the hole can’t be created. When leaving the dialog, this will be pointed out.

We hope that you will like the new features and that they will make your work easier. If you have any experience with the new functionality, please feel free to share it with us. We are also happy to receive further ideas for improvement, as we are constantly working on optimizing our software for you. Please feel free to give us feedback.