Successful Windchill implementation project

Windchill implementation project

In the first part of our little trilogy, you were introduced to Anja Liebhammer, the head of department for CAD design of one of the most innovative automotive suppliers in Germany. She just found out, that their Windchill implementation project is going to take ten times longer than they initially thought. Then they found an alternative with SMARTUpdate in part two. Now, we are very excited about their success.

A new chapter

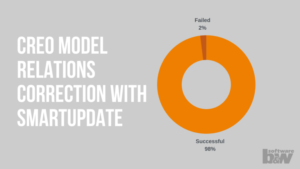

“We are honoured to be the messengers of this terrific news!” started Juliana. “I am the co-leader of the german key user team. I am responsible for the relation fixing project of the Creo models together with my colleague Dietrich Peters. Together we had the chance to experience some quantum leaps in the way we understood to handle our Creo models. The initial project was to correct the drawing program relations and the 3D model relations. By using SMARTUpdate of the company B&W Software GmbH in order to achieve that goal effectively, we not only managed to use the delivered relation engine with a success rate of 98%. We also discovered many functionalities in the software which would permit us to totally overhaul the Creo models to the current company standard.

“We are honoured to be the messengers of this terrific news!” started Juliana. “I am the co-leader of the german key user team. I am responsible for the relation fixing project of the Creo models together with my colleague Dietrich Peters. Together we had the chance to experience some quantum leaps in the way we understood to handle our Creo models. The initial project was to correct the drawing program relations and the 3D model relations. By using SMARTUpdate of the company B&W Software GmbH in order to achieve that goal effectively, we not only managed to use the delivered relation engine with a success rate of 98%. We also discovered many functionalities in the software which would permit us to totally overhaul the Creo models to the current company standard.

More than that, we can rely on it every time we plan a major change in the standard models. The batch functionality and the license model permit us correcting any count of models without any limitation. With SMARTUpdate, we managed to create a system which finds and corrects a multiple variety of errors already during the design process. We finally found a way to control the delivery delays of our projects and to constantly improve the quality of our Creo models. And the best thing is the peace of mind we have now, knowing that we can cope with the most challenges we encounter through unintentional errors while designing Creo models.

My colleague Dietrich will present you the details about all model properties we are now able to easily deal with. Dear Dietrich, the stage is yours!”

SMARTUpdate changed my life!

Slightly blushing hearing that, Dietrich approached the lectern and feeling his pulse go up. He started:

“SMARTUpdate changed my life! Two weeks ago, I started feeling depressed fixing relations by hand. Even if I did well, I had the feeling this task would never end. I was a regular designer and therefore as well honoured to be the co-leader of the team together with Juliana. And together with the other leaders and members of the key user team, we changed not only my and every individual’s life, but also the future of the company by controlling and minimizing the error sources during the design process. We just started a new chapter in our company’s history book.”

The significant details

“Our initial goal has been achieved already during the two-week test phase .” continued Dietrich after the applause subsided.

”We successfully managed to correct the relations for 98% of all 300K Creo Models. The remaining 2% are very rare and special cases among the legacy models, where the relations and the geometry must be redefined by hand.

Besides the set of 20 rules for the relations we were also able to identify the following model properties we can keep up to date:

- Change, designate, create or delete 85 different Model Parameters if necessary.

24 model features wich have to be renamed and seven start features to be edited or created if missing.

24 model features wich have to be renamed and seven start features to be edited or created if missing.- Create or remove the 28 Layers.

- Correct or create the 10 orientations.

- The tolerance type of all dimensions can be finally updated.

- Update and harmonize the units.

- All materials in all our models can be checked and changed if necessary.

- The detail options settings from the *.DTL file for all the models can also be updated.

- And finally, we can even use the protected parameter with the remaining errors for the gate-keeping functionality in Windchill.

With the help of SMARTUpdate and the defined rule set, we can also handle every new model we receive from our suppliers” said Dietrich and made a break. We just got ourselves a personalized jet drive for moving our Creo models to a new era!” He added, and the applause started instantly. He even noticed a benevolent smile from the CEO Martin Müller, and he happily smiled back.

One more thing

“There is one more thing I’d like to talk about.” Dietrich continued. “We have been following the work of Mr. Jan Stothfang. He defined during his time as a CAD admin a very extensive layer scheme, which we’ve been dreaming of implementing on our side as well. Thanks to SMARTUpdate, we can now overtake and adapt this layer scheme to our needs, and make sure, it is present in every model. Yet Mr. Stothfang did not stop here. He conducted a tremendous amount of work on the new field of Model Based Design. He tried out different ways to move from the paper-based drawing to the paperless 3D model together with the developer team from B&W Software. The result consists of several tools like SMART3DExport, SMARTAnnotate, SMARTColor and of course SMARTUpdate.

Because SMARTUpdate was originally his idea and because in the meanwhile he is CEO at B&W Software GmbH, many new features have been implemented in SMARTUpdate. Layer states, simplified representations, combined states and annotations can be created and changed if necessary. There could not have been a better timing for purchasing this software, as we planned to take the first steps in our company towards Model Based Design starting with Q1 of next year.

We are now ready to embrace the future. Thank you everyone!”

During the frenetical applause Juliana approached notably touched the lectern and after a short moment of hesitation she laid her hand on Dietrichs. Surprised he looked at her, and the light in their eyes was the proof, the future was indeed going to be bright.

Do you also want to share a success story with one of our tools? Contact us and we will make it visible.

This is a fictional story based on real events for informative and entertaining purpose. Any coincidence with real persons is not intentional.